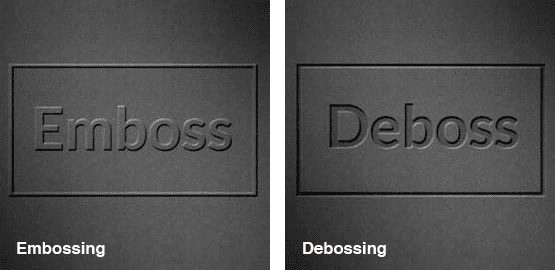

Embossing and Debossing

In order to produce a raised form or picture, embossing is applied to certain paper sections. When compared to the flatness of the remainder of the sheet, the embossed region takes on a three-dimensional appearance and creates a tactile and visual contrast.

When a high-end, custom look is sought, embossing is frequently utilised. Examples include wedding stationery, letterheads, folders, certificates, packaging, etc. Additionally, it serves as a security tool to stop counterfeiting.

How is embossing applied

The paper is sandwiched between two copper or magnesium dies. The raised design will be on the die that is positioned beneath the paper, and the recessed pattern will be on the counter die that is positioned on top of the paper. The paper is then forced into the recessed die by applying heat and pressure to the two dies, which causes the paper fibres to be compressed and creates the permanently embossed region.

Types of embossing

Blind Embossing

The term “blind embossing” refers to a raised region that is not printed. Without the use of any ink or foil, this offers a pronounced yet subtle contrast and can handle relatively minute detail.

Registered Embossing

This occurs when print, foil, or spot UV varnish are also utilised in conjunction with embossing (or a combination of more than one of these). To provide even greater contrast, a second embossed section might be employed.

Combination Embossing

The embossing is aligned to the picture such that the printed image is stamped out after it has been printed, foiled, or put in spot UV. Text and basic graphics are best suited for this technique.

Debossing

Similar to embossing, but with the metal dies switched around such that the region is stamped into the paper and creates a recessed (dented) area, is the process of debossing.

Similar to embossing, you can fill the area with ink or foiling or leave it plain and unprinted to only create the debossed look.

Things to consider before you start

Artwork

The ideal files for this technique are vector ones since they can easily be scaled up or down without losing quality.

Keep it simple: Since the embossing is the main attraction, stay away from shading and, if feasible, stick to one colour so that it doesn’t get lost in the print. This is especially suggested if you plan to emboss your materials in combination.

Choosing the embossed area

Less is more. It’s a matter of personal preference and should be tailored to the particular item in question, for example, you may want to have an all-over embossed or debossed pattern on an invitation or business card, with a registered or combination embossed area to contrast the background pattern. The wow factor of the embossing is maximised when it’s used sparingly.

Choosing the pattern and Paper weight

Think on how deep your embossing is. Small portions shouldn’t be embossed deeply since doing so will cause the paper torn. If using multiple layers of embossing, place the deeper levels in the less detailed parts to minimise paper damage.

If deep embossing is to be utilised, a high paper weight is advised since your paper must be thick enough to support the depth without being compromised. A thick weight paper with a deep emboss will produce an image with depth and detail.

Consider the reverse

There will unavoidably be a raised or recessed region on the opposite side of the sheet since the embossing or debossing process moves the paper to the opposite side of the sheet.

If you have any further questions about embossing or debossing then call us on 023 8087 8037 or email us.